An AC drive is an electronic device that controls the speed of an electric motor. You use an AC drive to adjust the current sent to the phase motor, changing its speed. This technology is used in numerous applications such as fans, pumps, compressors and conveyors. Using variable speed drives can save energy in the long run and reduce equipment wear and tear. When choosing a frequency controller, factors such as motor load, required accuracy and environmental factors must be considered. An AC drive can optimize production processes and save money.

Connecting an AC drive correctly is essential for efficient and reliable operation. Improper connection of the variable speed drive with output can lead to motor failures, breakdowns and possible danger to worker safety. Common problems caused by improper connection are overheating, motor failure and interference with other equipment connected to the same power grid. As a company, you naturally want to mitigate these problems. To avoid these problems, the AC drive must be installed accurately with proper wiring and grounding. Accurate connection of an AC drive can help companies minimize downtime. Contact us if you are unsure about connecting an AC drive.

Table of Contents

The requirements and materials

The necessary tools and materials

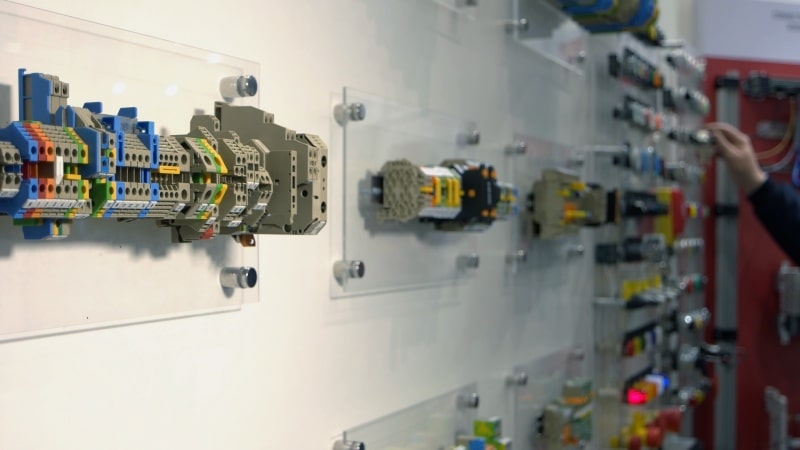

If you plan to replace your current regulator or install a new phase regulator, it is essential that you have the right tools and supplies. Having the right tools can make all the difference to a successful outcome. Choosing the best tools and materials can be tricky if you have no knowledge of the job. Gerbin Control is always available, whenever you need help during installation. Proper research and advice from specialists is very important here. Before you begin, make a list of needed items and materials. They must also be of good quality and durable to ensure long-term success.

OPEN CALCULATION

OFFER IN 5 DAYS

SUSTAINABLE INNOVATIONS

UL/CSA

AT HOME

Check that the AC drive is compatible with your system

Connecting an AC drive to your electrical system can improve performance, but it is essential to ensure compatibility. To connect a 230V AC drive, make sure its specifications match the voltage, current, frequency and correct power output of your system. If you’re not sure which one is best for your system, get a no-obligation consultation from us. By using the right AC drive and connecting it properly, you can increase efficiency and save on energy costs.

Contact our experienced innovator

Cees Brasser

With more than 26 years of experience at the helm of Gerbin Control, Cees Brasser is your expert on panel construction for the machinery sector. Discover how his knowledge and insight can take your project to new heights. Get in touch now!

The steps for connecting an AC drive

An installation of an AC drive should be done carefully, following the necessary steps. Here is an overview of the key steps:

- Provide adequate space and lighting: When working with electrical systems, it is important to have adequate space and lighting to work safely and identify potential problems. Make sure you have enough space to work comfortably and that you have a good view of the connections and cables. If the room is not adequately lit, first make sure you fix this by installing construction lights, for example. Following this first step more closely will make it easy to place the phase inverter.

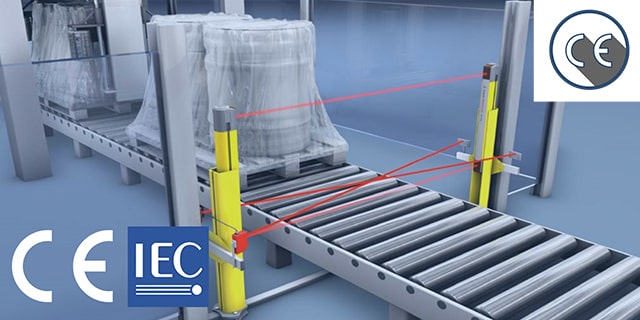

- Place the AC drive in a sturdy and dry place: An AC drive must be protected from water, moisture, vibration and shock. Make sure the location is stable and that the controller is properly secured to minimize vibration. The controller should also be in a non-humid environment to prevent short circuits or damage. To extend its life, it must be protected from dust and dirt. We recommend here that the controller be placed in a sealed cabinet or enclosure.

- Prepare the cabling and make the connection to the main power: Before connecting the AC drive, make sure that the main power is turned off and safety measures are taken. Safety measures include wearing protective clothing and using insulated tools.

- Connect the AC drive to the motor: To correctly connect an AC drive to a motor, identify the motor terminals and connect each terminal to the corresponding terminals on the AC drive. The U, W and Y terminals must be securely connected with safe insulation to prevent short circuits. Check that all wires and cables are installed without damage. When in doubt, always seek professional guidance if you are unsure about connecting the motor.

- Connect the AC drive and external control cables: It is important to determine the type of external control used. Next, the proper cable to connect it to the AC drive will need to be determined. Usually this is a standard RS-485 or Ethernet cable. The cables should be the right length and well insulated to avoid potential problems here as well.

- Program AC drive settings: It is essential to adjust the maximum/minimum frequency, acceleration time, deceleration settings and motor protection of an AC drive to enable optimum performance. The proper configuration of the AC drive should be based on the specific application and characteristics of the connected equipment. This will require consideration of RPM requirements and power differential. By properly configuring the AC drive, according to a clear installation manual, it will not only run smoothly, but also reduce breakdowns and extend its life.

- Test the configuration of the AC drive: Testing the configuration ensures that the AC drive is properly connected and programmed. This will make the phase motor run smoothly. During the test, various parameters should be checked, such as speed, torque output, current and temperature. Performing the test carefully ensures that the AC drive slowly controls the motor correctly and protects it from overload and overheating.

For safe and efficient connection and programming of the AC drive, we recommend following these steps carefully. In addition, it is recommended that you always consult the manufacturer’s manual and feel free to contact us if you have any questions about this.

Your electrical engineering ambitions, our mission

Our expert team at Gerbin Control is ready to turn your electrical issues into concrete solutions. Are you ready for the next step?

Important points to consider when connecting an AC drive

Related Articles

What trends in panel building can we expect for 2024?

The world of panel building is one of constant evolution and innovation. As technology advances, market expectations are increasing. But what trends in panel construction can we expect for 2024? At Gerbin control, an industry leader in producing high-quality electrical panels, we took a look at what the future holds for us.

The role of reuse in panel building within the circular economy

When building modern infrastructures and systems within industry, panel construction plays a crucial role. But have you ever wondered how panel construction can contribute to

The importance of certified panels for safety and quality

In an era where technology and innovation go hand in hand, Gerbin Control has established itself as a leading panel builder. Safety and quality are

Are energy-efficient panel systems the key to a better planet?

In a world where sustainability is no longer a luxury but a necessity, we are constantly looking for ways to reduce our carbon footprint. One

The best choice of materials for durable panel construction

If there is one thing we are passionate about at Gerbin Control, it is the innovation and quality that goes hand in hand with sustainable panel construction. When choosing the best materials for panels, there are several factors to consider. In this article, we dive deeper into those choices, drawing on our years of experience in the industry.

How panel systems are the bridge to the Internet of things

At Gebin Control, we recognize the revolutionary power of panel systems and their integration into the emerging world of the Internet of Things (IoT). In