Table of Contents

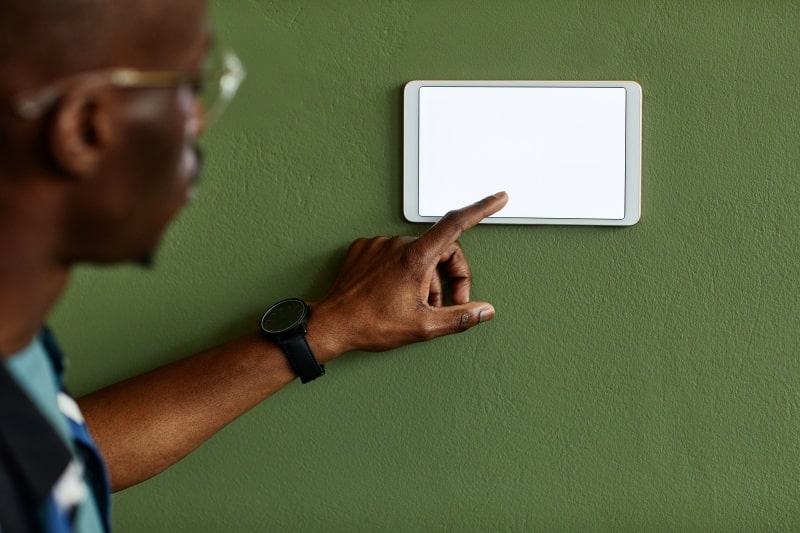

HMI screens

HMI displays, also known as Human Machine Interfaces, are graphical user interfaces used to enhance communication between a machine and an operator. This way, your operators can monitor and control the machine more efficiently through real-time updates of important information about the production process. Panel Master is used to create the various displays that carry the data that can be extracted from PLCs, for example, and also sent to that PLC. This makes it easier for operators to quickly understand what is happening with the machine.

HMI screens are user-friendly, available in a variety of sizes and resolutions, and made of rugged materials that can withstand industrial conditions. This is in most cases an operator panel with color display. Moreover, they are flexible and adaptable, so they can be adapted to a variety of machines and production environments. Optionally, the basic panel for HMI can be protected by a robust aluminum housing or plastic housing.

In short, a touchscreen panel is very useful for any machine and production environment because it facilitates operator control of the machine and increases productivity and efficiency.

OPEN CALCULATION

OFFER IN 5 DAYS

SUSTAINABLE INNOVATIONS

UL/CSA

AT HOME

Why are HMI screens important?

HMI screens are important for a number of reasons, including:

Improved productivity: HMI screens provide operators with up-to-date insight into the status of both the machine and the production process, leading to improved productivity and efficiency.

- Easy operation: HMI screens facilitate operation and allow operators to quickly understand and accurately control the state of the machine.

- Reduced downtime: HMI screens help reduce the downtime of your machines and improve productivity and reliability.

- Improving safety: HMI screens help ensure operator safety by promoting efficient machine operation and minimizing the risk of accidents and damage.

- Data analysis: HMI screens often have capabilities for current data, which can be used to detect problems.

In short, HMI screens are important because they help the operator monitor, increase productivity, reliability and safety by providing remote access to the machines.

The role of HMI screens in industry

HMI screens are essential to industry and manufacturing. A lite panel can be used in a variety of applications. The simple touch panel with color screen keeps monitoring and controlling production processes. In addition, they offer several important advantages. HMI screens give companies timely insight into their production processes so they can quickly identify and resolve any problems. HMI displays allow companies to better integrate other systems and collect and assess real-time data, allowing them to react quickly to changes in production processes. Lastly, using HMI screens is an excellent way to streamline and automate production operations, resulting in increased productivity and efficiency.

Technical specifications

Certifications and the protection

Certifications and the degree of protection are important considerations when choosing a product for modern applications. The degree of protection determines the degree of insurance against physical and environmental stresses, for example, dirt, water or vibration. Certifications confirm that a product meets certain quality requirements. Here are a few important factors to consider in safety assessments:

Degree of protection: Knowledge of the product’s degree of protection is essential for industrial applications. Products that offer better protection are more resistant to harsh weather conditions and require less maintenance.

Certifications: Products with certifications such as CE, UL and CSA are tested and verified to meet strict safety and quality standards. This adds another layer of reliability for the user and guarantees performance.

Application: Use the environment and purpose of the product as a guide and choose an appropriate level of protection and certification. A laboratory that must be strictly clean will require more stringent protection than a less critical environment.

Future-proofing: To future-proof the products, companies need to consider how the environment may change and whether the certifications and protection standards of the products need to be adjusted over time.

Contact our experienced innovator

Cees Brasser

With more than 26 years of experience at the helm of Gerbin Control, Cees Brasser is your expert on panel construction for the machinery sector. Discover how his knowledge and insight can take your project to new heights. Get in touch now!

Connections and communication protocols

Proper connection and communication protocols are essential for establishing and maintaining communication between multiple electronic devices and networks. After all, these protocols determine the quality, stability and durability of the connection.

There are various connection and communication options, such as serial connections, Ethernet or Wi-Fi. Each has its own advantages, such as higher speed, higher bandwidth, heavier protection or easier installation. Always contact a specialist to make the right choice.

By using the right connections and communication protocols, companies can become more productive and cost-effective. In addition, these connections and protocols can increase system stability and uptime and reduce potential accidents.

Touchscreen and control options

Touchscreens are now an integral part of modern industrial systems, offering a variety of control functions. They make operating systems easier and faster, increasing production efficiency. The benefits and operating features of a touchscreen are explained below:

Easy to use: Touchscreens are user-friendly, replacing traditional buttons and switches with an intuitive operator interface that reduces the chance of operator error and improves the user experience.

Customizable: Touchscreens offer the advantage of being customizable to specific needs and applications, allowing companies to control their production process more efficiently and effectively.

Real-time monitoring: Touchscreens provide real-time observation and management of the manufacturing process, enabling control and increased efficiency.

Mobile compatibility: The compatibility of touchscreens with mobile devices allows companies to extend control of their operations beyond the production process.

Security: Touchscreens can be equipped with security measures such as password protection and authorization, allowing companies to better secure their production operations against unauthorized access and tampering.

Touchscreens with their versatile operating capabilities are essential in today’s business world. It is an intuitive and efficient way to manage systems and streamline production. Companies looking to speed up their workflow should consider using touchscreens in their operations.

Your electrical engineering ambitions, our mission

Our expert team at Gerbin Control is ready to turn your electrical issues into concrete solutions. Are you ready for the next step?

Installing HMI screens

Choosing a suitable installer for HMI screens is there important to minimize maintenance and optimize productivity precisely. There is a wide range of installers but a few actually specialize. A qualified installer has the knowledge and capabilities to guarantee you that the system is installed properly. This guarantees you that the system operates effortlessly and effectively, reducing failures and improving performance. In addition, a professional installer can offer advice on how to make the best use of the system and address any problems. In fact, there is a wide range of screens that all also possess a range of applications.Finally, a trained installer can provide ongoing maintenance and assistance so that your HMI screens continue to perform optimally over time. Do you have questions about installing the right HMI screens? If so, please contact us without obligation.

Related Articles

What trends in panel building can we expect for 2024?

The world of panel building is one of constant evolution and innovation. As technology advances, market expectations are increasing. But what trends in panel construction can we expect for 2024? At Gerbin control, an industry leader in producing high-quality electrical panels, we took a look at what the future holds for us.

The role of reuse in panel building within the circular economy

When building modern infrastructures and systems within industry, panel construction plays a crucial role. But have you ever wondered how panel construction can contribute to

The importance of certified panels for safety and quality

In an era where technology and innovation go hand in hand, Gerbin Control has established itself as a leading panel builder. Safety and quality are

Are energy-efficient panel systems the key to a better planet?

In a world where sustainability is no longer a luxury but a necessity, we are constantly looking for ways to reduce our carbon footprint. One

The best choice of materials for durable panel construction

If there is one thing we are passionate about at Gerbin Control, it is the innovation and quality that goes hand in hand with sustainable panel construction. When choosing the best materials for panels, there are several factors to consider. In this article, we dive deeper into those choices, drawing on our years of experience in the industry.

How panel systems are the bridge to the Internet of things

At Gebin Control, we recognize the revolutionary power of panel systems and their integration into the emerging world of the Internet of Things (IoT). In