Switchboards are indispensable components of many electrical systems. They function as the heart of the machine to manage the power supply to various devices and protect against overloads. The control cabinets contain safety switches that mechanically shut down in the event of an electrical fault, improving safety. Switchboards are also adaptable and expandable according to a company’s specific requirements, making them both reliable and adaptable.

Table of Contents

The contribution of RFID identification during switchgear commissioning

RFID technology, or Radio Frequency Identification, is becoming increasingly popular for switchgear commissioning. RFID labels can be applied to control cabinet components so that each component can be quickly identified and checked. This makes detecting any problems during installation and commissioning much easier and also provides a more streamlined approach. In addition, RFID tags can be used to store information about the switch box, such as the model and serial number, which can be used in the future. To give an example, process-safe identification with the UHF RFID control is used for identification on injection nozzles, identification of liquids and identification of chocolate. The RFID solution is further deployed for detection in bottle identification and hose connector identification. By using RFID remote sensing during switchgear commissioning, companies can ensure that their systems are correctly installed and working properly.

OPEN CALCULATION

OFFER IN 5 DAYS

SUSTAINABLE INNOVATIONS

UL/CSA

AT HOME

Steps for commissioning a control cabinet

Collecting supplies

Getting the essential parts is a crucial part of any activity or assignment. It helps optimize output and saves time by making sure every necessary thing is at your disposal. Moreover, it reduces pressure and doubt by guaranteeing that you are ready and have everything you need to have. When doing a homemade job, preparing for an occasion or embarking on a new pastime, gathering the right materials is an essential progression.

Safety

The security of our customers is paramount, and we take our duty to keep them and their data safe extremely seriously. To ensure that your data always remains confidential and secure, our website is reinforced with the latest technologies, such as SSL encryption and regular security updates. In addition, strict internal principles and protocols have been installed to protect our users from crime and mistreatment. At the point of high information security, we take no chances and use all available means to give our users security and provide them with the ideal experience on our page.

Technical drawing explanation

Technical drawings are indispensable for understanding and executing projects efficiently and productively. They provide a clear and comprehensive visualization of the parts, dimensions and composition of a structure or asset. This allows professionals, engineers and other experts to obtain safe and accurate facts about the blueprints they are dealing with. Here you will find technical drawings created by expert professionals, using the latest software and technology, so you can always be sure of quality and precision.

Implementation

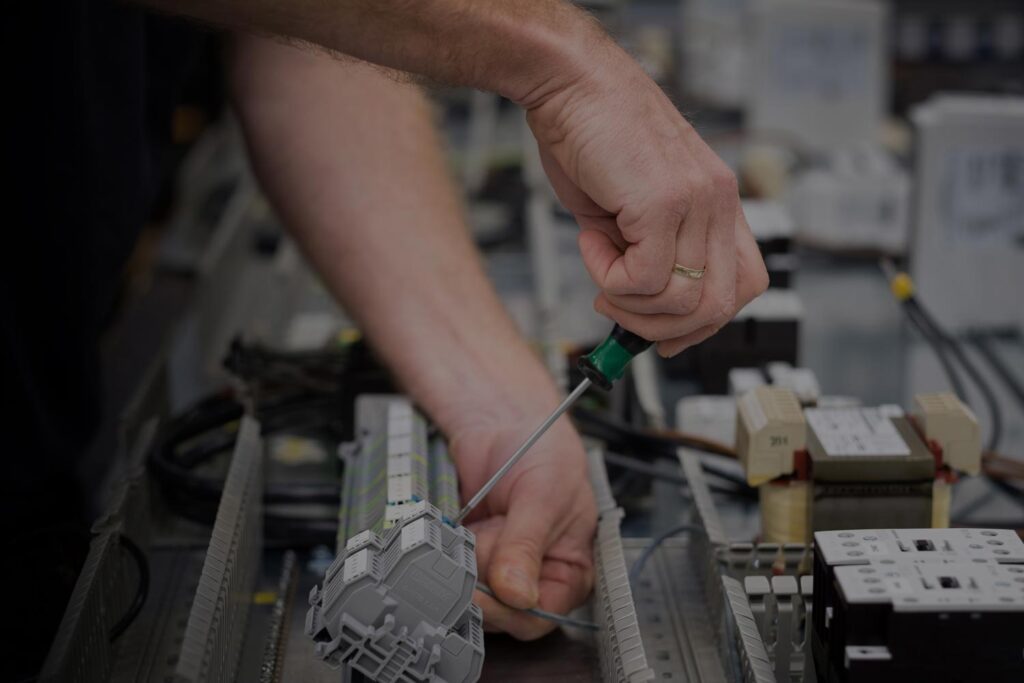

Connecting the cables

For the functionality and safety of any electronic device, it is essential to connect the proper cords. This ensures that power and data are transmitted accurately and quickly between different machines. It is necessary to choose the right cables for the exact device and installation you are performing. Failure to adhere to proper connection methods may result in substandard performance, malfunctions or even destruction of the device.

Installing the components

Component installation is an essential step when rebuilding, repairing or upgrading a product or the entire system. Precise, efficient and fast installation is critical to avoid problems and confirm that the product or system is working experimentally. Whether you’re a skilled technician or want to enter the business as someone who just performs tasks, our manuals provide step-by-step explanations and visual aids to help you with every installation.

Contact our experienced innovator

Cees Brasser

With more than 26 years of experience at the helm of Gerbin Control, Cees Brasser is your expert on panel construction for the machinery sector. Discover how his knowledge and insight can take your project to new heights. Get in touch now!

Testing and checking the connections

Testing and machinery quality control monitoring of connections is an essential part of installing or safely maintaining electronic devices. It ensures that everything is connected efficiently and working as expected before the device is put into service. It also prevents potential problems in the future, such as malfunctions or even damage to the device. Moreover, it gives you the assurance that the machine is operating accurately and safely.

Factory Acceptance Test (FAT).

The Factory Acceptance Test (FAT) is an important step in the commissioning of control cabinets. It is made to ensure that all components work accurately and that the cabinet meets the expectations of the project. The FAT includes a series of tests, including ocular examination, electrical examination and functional assessments. Once these investigations are successfully completed, the cabinet can be approved by the customer and put into service.

The System Acceptance Test (SAT).

The System Acceptance Test (SAT) is the final phase in the commissioning of switchgear cabinets. It is carried out to ensure that each element works correctly and that the unit meets consumer expectations. The SAT involves a sequence of tests, including visual examination, electrical assessments and operational assessments. Once these investigations are successfully completed, the cabinet can be confirmed by the buyer and put into use.

After commissioning is complete

Documentation

Documentation is indispensable for expert and productive project management and knowledge preservation. It provides details and instructions about goods, systems and methods, making them easier to understand and use. Whether you’re looking for special product data, background details on an entire system or comprehensive manuals, our documentation has the answers needed to complete your projects without hesitation.

Quality control

Inspection, testing and preventive maintenance are an integral part of every production cycle, verifying that products meet predetermined rules and descriptors. In addition, it prevents potential problems such as product dysfunctions or recalls, ultimately saving time and money. Expenditures on effective inspections and the selection of professional personnel are necessary measures to ensure that each item meets quality standards and meets customer expectations.

Your electrical engineering ambitions, our mission

Our expert team at Gerbin Control is ready to turn your electrical issues into concrete solutions. Are you ready for the next step?

Resolving any problems

Problem solving is an indispensable part of any task or object, whether you are a specialist or a do-it-yourselfer. One way this is done is with tool identification detection. It is necessary to respond quickly and effectively to problems to prevent them from occurring and to ensure that the product or system functions excellently. Our experts are constantly striving to improve and refresh our troubleshooting data so that you are always up to date with the most advanced methods and techniques.

Is it necessary to hire a professional for commissioning?

Hiring a specialist to install electronic equipment or structures is regularly necessary for several reasons. A professional has the right expertise, skills and knowledge to carry out commissioning quickly and cleanly, and fix any problems. Hiring a professional company will also save time and money in the long run because the device will work properly and be less likely to have problems. Generally, it is wise to hire an expert to set up the switch boxes or other electrical elements.

Related Articles

What trends in panel building can we expect for 2024?

The world of panel building is one of constant evolution and innovation. As technology advances, market expectations are increasing. But what trends in panel construction can we expect for 2024? At Gerbin control, an industry leader in producing high-quality electrical panels, we took a look at what the future holds for us.

The role of reuse in panel building within the circular economy

When building modern infrastructures and systems within industry, panel construction plays a crucial role. But have you ever wondered how panel construction can contribute to

The importance of certified panels for safety and quality

In an era where technology and innovation go hand in hand, Gerbin Control has established itself as a leading panel builder. Safety and quality are

Are energy-efficient panel systems the key to a better planet?

In a world where sustainability is no longer a luxury but a necessity, we are constantly looking for ways to reduce our carbon footprint. One

The best choice of materials for durable panel construction

If there is one thing we are passionate about at Gerbin Control, it is the innovation and quality that goes hand in hand with sustainable panel construction. When choosing the best materials for panels, there are several factors to consider. In this article, we dive deeper into those choices, drawing on our years of experience in the industry.

How panel systems are the bridge to the Internet of things

At Gebin Control, we recognize the revolutionary power of panel systems and their integration into the emerging world of the Internet of Things (IoT). In